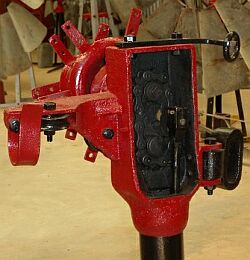

The chain driven IXL windmill was a pretty unusual machine and was registered under 'Australian Commonwealth' patent No. 4762-17828 issued about 1910 or 1911. The earliest advertising collected for it was in mid May 1910 when the company offered not only the windmill with its "...perfect mechanical action...", but troughing, pumping plants, poison carts, Bosker fumigators, fire fighters, water carts, Gibbin's ploughs, buggy and sulky wheels, patent adjustable channel tyres and steel wheeled lorries etc.

Although at first glance, because of the equal sized sprockets, the mechanism may appear to have utilised direct drive this is misleading. Typically the wind wheel went around twice for a single pump stroke because the pump rod attachment was connected onto the chain and travelled a full circuit of it and not a circuit of the sprocket. Tension was kept on the chain with the adjusting eye bolt which can be seen on the front of the mill below the hub shaft.

The use of a chain drive also allowed the designers to claim another advantage for their mill in that it has about 60% less side movement in the drive than a conventional geared mill. This allows for a narrower head casing and a more even application of force on the upstroke as the angle of application does not change.

The IXL is a rare Australian example of a fixed side vane being used to turn the head out of the wind instead of the offset hub shaft which was common to most more modern windmills and used on other windmills from the same company.

In the first known year of production there was a fitting on top of the head somewhat resembling a tow ball but due to the poor reproduction of the particular advertisement it is not possible to conclusively state what function it served. However it has been suggested that it was an oil dripper reservoir which lubricated the drive chain. This is entirely possible because the same illustration does not show the oil reservoir designed for that purpose which sat just below the idler sprocket and applied oil to the drive chain with an oil tripper wire automatic oiling device.

The IXL had a large reservoir in the nose section of the main casting which provided lubrication to the hub shaft using a chain ring oiler and included a brass or copper pipe running under the nose casting to circulate the oil.

By 1911 the 'tow ball' had disappeared, the pump rod changed and the chain oil reservoir is shown. The 1911 as with the 1910 version had the top tail hanger bracket bolted to the top of the main casting but there now appears to have been a different tail spar buffer in use. By the drawing this may have been a coil spring with an arrangement similar to an engine valve through it. The only confirmed sizes for these mills in 1912 are 8, 10 and 16 foot although there is also a testimonial for a 9 foot mill in 1911.

From mill number 1000 improved swivel and wood guide blocks were fitted as well as the patented spring shock reducer. This version of the IXL was advertised until at least mid December 1914 and earlier that year in February over 1250 mills were advertised as being in use.

By mid February 1916 a new version of the windmill was being advertised and there were then over 2,000 in use. Models at this time were available in wind wheel sizes from 6 to 20 foot.

By then there had been a few more changes in the design especially in the furling system. The top tail hanger bracket, which had been bolted to the top of the main casting, was done away with and a replacement of quite different design was now bolted to the righthand side of the casting. This not only acted as an attachment point for the tail hanger but the short chain now fitted on the top end of the tail hanger bent around the curved plate to keep the hanger away from the main casting's pressed tin back cover. The tail spar buffer which had been mounted at the end of the furl arm was shifted to be alongside the main body of the mill and was now a large flattened ring shape.

'Geo. E. Fortescue & Sons' also incorporated shock absorbing compression springs in the furling system to cushion the tail spar from damage as it snapped back into position during sudden lulls in high winds. Similar compression springs were used in the pump rod system to take the knock out of the mill as it went over or took up the stroke.

By 1919 the company is boasting of repeat orders from the New South Wales 'Dep't of Agriculture'. At some time during or before 1925 the main casting which had originally included the nose was redesigned to be cast in two pieces which had to be then bolted together. The idea behind this was to facilitate easier remetalling of the hub bearing should it become necessary.

Parts lists for 1925 note a new and old design of pump rod, which they show as a pitman. The older version has a hollow ball at its lower end while its replacement has a threaded end. Both old and new design styles of pump rod shock reducer are also listed.

In 1925 the IXL mill seems to have been available with wind wheels of 8, 10 and 12 foot using two wind wheel rings, and 14, 16, 20 and 22 foot using three wind wheel rings. The 22 foot size may be doubtful.

Advertising in the Southern Eastern States suggest that the company sold direct or at least advertised direct to the market. In Western Australia records exist of sales in Perth in 1912 resulting from local advertising but these may have been sourced direct from New South Wales. The first recorded local agents were 'Elder Shenton & Co' during the period including 1915. The company continued as agent after changing their name to 'Elder, Smith & Co, Ltd' by 1922 and continued selling windmills until at least 1932.

In Queensland in 1925 it was sold by the old firm of 'Smellie & Co., Ltd' in Brisbane. This company had a long association with windmills going back at least to 1911, when they advertised the imported Aermotor brand.

The latest date recorded for advertising for the IXL windmill is September 1932.

The Morawa Museum's example of an 8 ft IXL windmill was kindly donated by Bob Parkinson of Geraldton and restored by museum members.