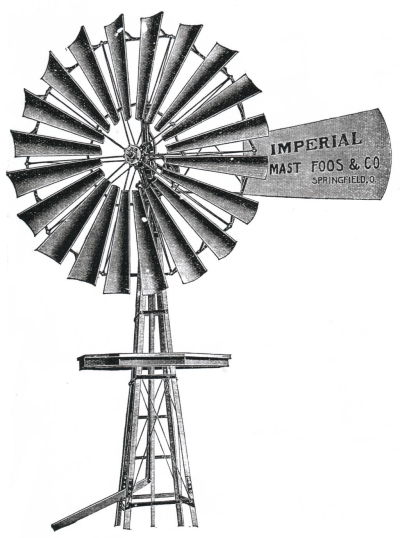

This all metal open geared windmill was first manufactured by Mast Foos & Company in the USA in 1896 as a pumping mill. The exception to this is that the 10, 12 and 14 foot models could also be specially order in a direct action version if required.

This was an unusual head as it was in three basic parts. The first of these was a mast pipe that sat down through the tower cap and extended up through the full height of the engine castings. The next major component was a casting which pivoted on the mast pipe and to which the wind wheel and all the engine parts of the head were attached. The third component also pivoted on the mast pipe and acted as the hinge for the tail and the mounting point for the regulating spring.

The hub shaft was set slightly to one side of the turntable centre to assist in regulation. A powerful concentrically coiled spring housed in a disc shaped cover attached to the tail hinge casting was used to keep the wind wheel facing into the wind. When the wind conditions became to strong and forced the tail to fold towards the wheel a band brake on the hub was also deployed. The tension on the spring can be adjusted to set the sensitivity of the mill to strong winds. There appears to have been some concern from the public about this spring as an early catalogue included the following paragraph on the matter.

"...But should one of these springs break, the owner need not lose the use of the mill for one hour, as all that is required is to fasten a rope to the inner end of the lever in the tower and attach a weight to the rope sufficient to hold the wheel in the wind, and the mill will govern as well as any mill that is governed by a weight."

The pinion gear ran inside an internally cut gear which drove a pitman arm attached to a wrist pin at the back of the main gear up to a crosshead in a parallel sided guide to create the reciprocating motion for the pump rod and centralise it in the mast pipe. A steel pump rod fastens to the crosshead and passes back down through the mast pipe.

The spokes for the wind wheel screw into the hub in pairs and attach to an outer ring made up of a series of straight bars. Fairly narrow galvanized blades are riveted to an inner and outer bracket in pairs and the outer bracket then bolts onto the outer ring, while the inner bracket is bolted to braces between the spokes. This allows a damaged pair of blades to be replaced without interfering with the integrity of the wind wheel frame.

Removable white metal bearings are used throughout the windmill.

The Imperial windmill stayed in production into the mid 1920's.

There were four tower options available with the mill. The more usual used a tower cap that could be fitted to either wooden or galvanised steel four legged towers. There were also three legged galvanised steel towers available for six and eight foot mills. The last two options were a casting to fit the head onto a single post and to fit the head between two wooden posts.

The example of the Imperial windmill in the Morawa Museum was restored and donated by Jim SAWYER of Dalwallinu, WA, in January 2009. It is one of only two known to have been found in the Wheatbelt area of Western Australia.