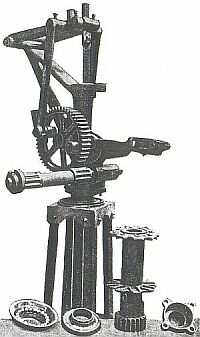

In 1903 a new James Alston & Sons windmill based on the 1900 single crank model was introduced to the public and became one of the company's most successful designs.

This model of mill was available in a large range of wind wheel sizes and there was some variation in the overall design because of this. However the broad concept stayed the same. The change to the rocker arm required for the new model, resulted in a more rigid casting without the very wide floating end required by the old design. The Pitman arms now fitted outside the rocker arm and held grub screws to fix the crosshead pin. Shallow oil wells were also cast into the rocker arm lugs of the ten foot model and it is assumed a larger oil well was built into the pump rod head, similar to the later 1910 version. Both the main gear and the crank fitting were equipped with screw in oil or grease fittings to lubricate the movement of the Pitman arm.

The 1903 version had one relatively major change made to the hub/pinion design used by its 1900 ancestor, and this was the inclusion of two sets of roller bearings which were presumably similar to those seen on the 1910 model. In addition, the earlier screwed cap was altered to a clamped cap held on by two or more bolts.

ALSTON made a point of including the word patent in virtually all of his advertising in this period and in fact this windmill is often referred to as the "ALSTON Patent Double Crank Windmill". The company did not seem to be too worried about a major competitor emerging in Tasmania and this was the only state that does not seem to be covered by a patent document. The 'Double Crank' patent was also protected in the USA in 1903, and in New Zealand by 1910. Advertising informed the public that the windmills could be erected by "any intelligent farm hand." Presumably by inference the property owner, as a cut above this would have no trouble at all.

One interesting point in the notes on the windmill for the 'Victorian Royal Agricultural Show' of 1903, was the attention given to the fitting of the windmill onto a: - "building such as a barn, or stable, or any other structure. All that is required in such a case is to bolt a piece of hardwood, 4" x 4" and 3 ft. in the clear above obstructions, and fasten the same by means of four bolts." Very precise, but not overly helpful instructions. This style of fitting is rarely mentioned in Australian advertising of this late date, and is more typical of American literature and earlier advertising drawings in Australia of American manufactured windmills. There is however some evidence that the idea was used in Australia, but may be more related to the use of the windmill as a power supply for gristing etc. than pumping.

Either James ALSTON, or someone else in the company, was a very astute salesman, and didn't miss a pitch in their advertising. By 1908 they were making sure that the buying public realised that their mills were made in Australia with no import duty to pay, that they had the largest sales of any windmill in Australia and, for the freight conscious, the head and part of the tower would pack into one box.

The Double Crank model was available in 8, 10 and 12 foot versions from at least 1907 and, from testimonials, it appears that there was an 18ft version available by that date as well. In 1908 a 20ft version is included. Price wise, the 8ft Double Crank was listed at roughly 50% more than was being charged for the ALSTON Single Crank of the same size. Advertising continued for the 1903 Model until at least July 1912.

An updated version of the Double Crank windmill was introduced, known as the Patent 1910 Double Crank Steel windmill. For ALSTON that is a significant year because it was then that he introduced the oil bath Gearless Mill and the company joined a revolution in windmill design, which affected the whole windmill manufacturing world. The Gearless, although not a geared mill, (as is obvious by the name!) is certainly a sophisticated oil bath design of a simple and revolutionary type. It marked the beginning of an interesting period in windmill development and windmill marketing, where the new sealed engine competed with the familiar machine with exposed mechanical parts. The new Gearless windmill competed directly with the Double Crank model from its introduction in 1912, when Alston began offering the equivalent sizes of both models at the same price. So the buying public had quite a diversity of choice within the same brand. This price parity continued on until at least 1918.

This was all in the future for the 'Double Crank' mill but assuredly sealed its eventual fate, although it appears that there were some supplies of the model available up to about 1934. Even at this late date they were still being sold at the same price as the Gearless windmill. By about 1912 the 1910 Patent ' Double Crank' was available with wind wheels of 8, 10, 12, 14, 16, 18 and 20 foot. The wheel had three blades between successive spokes in all the sizes and used a single sheet of corrugated iron for the tail vane in all versions except the two largest, which had one sheet either side of the tail spar with a space between and more of a swallowtail shape than the usual rounded design.

The weight of the heads of these mills ranged from 199.6 to 907.2 kilograms. At that weight the largest versions may have had the main casting built in sections for convenience in transport and erection. The pulley mount, for the furling system in particular, projects a considerable distance to the side of these mills and would be a candidate for this type of design.

ALSTON advertising, as is the case with many other brands, emphasised the sensitivity to wind change of the turntables used in their mills. In the case of the 'Double Crank' mills this was accomplished by sitting the curved surface of the bottom of the main casting in a cup shaped casting. This created a ball and socket joint when it sat in the chilled casting, holding a ring of tempered steel ball bearings, which in turn sat in the cup like top tower casting or tower cap. From the design of the main casting of the Morawa Museum's 1903 mill, it would appear to have used a similar turntable to the 1910 patent.

The eight foot version of the 1910 Patent did not have roller bearings in the hub and in addition appears to be the only one of the range which did not have flat bars bolted onto the main casting to hold an offset tail hanger. Instead, it used a casting similar to that used on the 'Single Crank'. This pivoted on a bolt in the main casting near the top of the mast pipe. In addition, the shut off chain pulley was mounted in a bracket on the rocker arm support section of the main casting. General statistics list four spokes in the wind wheel, gearing of 3:1, a choice of a 125 and 175 mm pump strokes, running at about 25 to 27 strokes per minute. The 10ft version has six spokes, gearing of 2.5:1 and a choice of 175 and 225 mm strokes. The 12ft mill has eight spokes, the same gearing as the previous size and strokes of either 200 or 250 mm.

Advertising suggests that the fourteen and sixteen foot mills which are grouped together in catalogues may have been different wind wheels on the same main casting. They shared the same statistics of eight spokes plus strokes of 175, 225, 275 or 325 mm. The small difference in weight between the two heads could easily be attributable to the wheel.

In 1918 and possibly in other years the 14ft mill was listed with two configurations. One as light and the other as heavy. The heavy appears to be the standard mill but the light shares the pump strokes of the 12ft mill and is priced in between that and the 14ft heavy mill, suggesting that it may have been built on the smaller and lighter motor. Interestingly enough the 'Gearless' mill matched this size configuration in 1918 as well so that both mills had an identical price and size range. The two largest mills of 18ft and 20ft also appear to share the same castings. They have ten spokes and available strokes of 250, 300, 350 and 400 mm.

Lubrication for these mills varied a little depending on size but generally the model used cast in oil reservoirs. Some use of screw in grease cups was made particularly on the hub. The eight, ten and twelve foot sizes and maybe the larger four were fitted with cast in oil wells in at the bottom of the Pitman arms. The rocker arms of the various sizes seem to have had a number of different lubrication devices and there were possibly variations in the systems used for the main gear shaft as well. In the case of the 8ft 1910 model, this was an oil well cast into the clamp block.

The model on display at the Morawa Museum was donated by E. & R. NICHOLAS of Gutha.