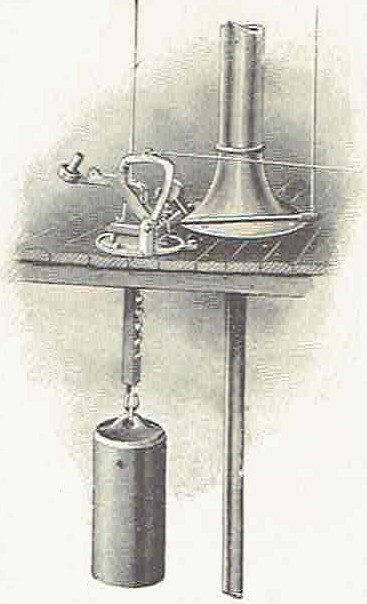

Many windmill manufacturers made tank regulators for their windmills and the Aermotor Company was no exception. The general principal of a tank regulator is that once the tank was full of water, the windmill would be automatically furled by this device to make it stop pumping, and then when the water level in the tank dropped, the mill would start pumping again.

The 1899 Pattern Aermotor Regulator is a product that appeared and then disappeared in only a three to four year period around the turn of the twentieth century. This regulator was introduced with the 1899 Model Pumping Aermotor windmill, which was a "pull-in" style mill. This meant that tension on the control wire pulled the windmill wheel and vane assemblies apart in order to swing the vane around perpendicular to the plane of the wind wheel. The mill pumped water only so long as tension was maintained by the control wire, and should that wire break or become loosened, the mill automatically would shut off. This was a good protection for unattended mills when turbulent winds came. A regulator for a "pull-in" windmill had to operate to reduce and then restore that control wire tension.

The Morawa Museum example of the 1899 Aermotor regulator is mostly complete, though we think there is a lever missing and obviously the weight that hangs from the spring-loaded hook. It is rare to find one of these regulators, even in their country of manufacture, the USA.