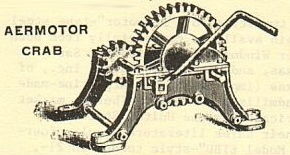

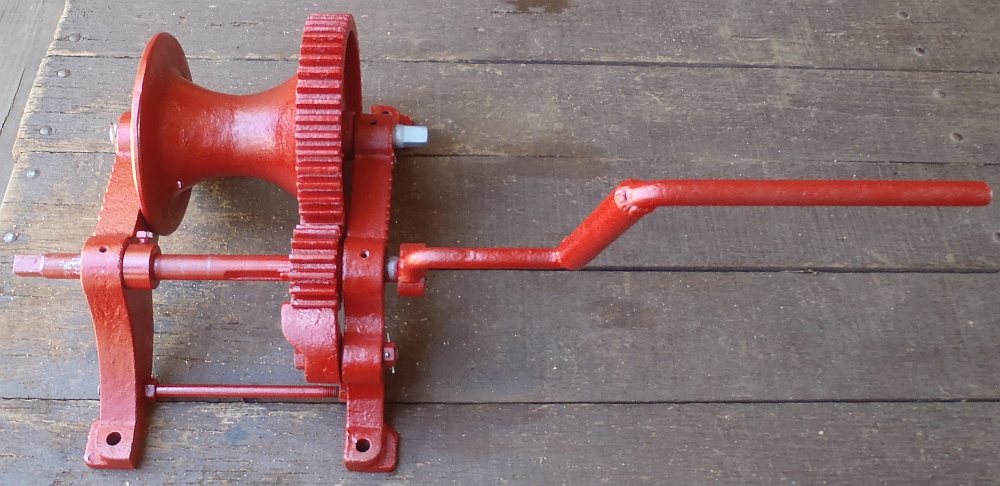

Crab winches have many uses but one of them is for raising windmill towers. The Aermotor Company of Chicago, Illinois, USA were making their crabs as early as 1893. This example travelled all the way from Chicago to the northern part of Western Australia where it was discovered and identified on an outback station in 2014. The handle may not be original as it has been broken and repaired in a couple of places. The cable that was wound around the drum has also been removed.

Aermotor were making their crabs and advertising them as early as 1894. In Western Australia, the Aermotor agent, W. D. Moore and Co. Ltd., were still advertising Aermotor Crabs in their June 1937 price list.

Several Australian windmill manufacturers are known to have made their own crab winches. These include Southern Cross, Comet and IBC. There are both single purchase and double purchase crab winches advertised in their catalogues. Some are made from cast iron and others are of steel construction.

The principal method of using a crab to raise a windmill tower is basically the same, regardless of the manufacturer of the individual winches. The basic instructions given for raising a windmill tower using a crab winch are as follows.

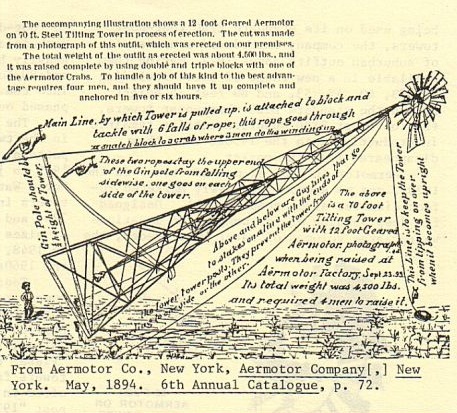

Assemble the tower and mill so it is laying flat on the ground. Bolt a two-inch plank to lower end of posts on ground, through the holes anchor posts are attached, long enough to project two feet on either side of tower. The gin pole or shear should be one-half the height of tower, main rope one and a half times, hoisting rope four times, two guy ropes one and a half times the height of tower to be erected. One single and double steel tackle block, one Crab winch completes the outfit to erect towers. Place lower end of shear on plank at bottom of tower and incline shear towards tower about 25 degrees, attach main rope to tower at platform and place it in crotch of shear, fastening same to hoisting rope, as shown in illustration. When all is in readiness, raise tower slowly a few inches and stop to insure all is safe; proceed to raise carefully, the men at guy ropes on either side and to rear of tower to play out rope as tower raises. When tower is raised so hoisting rope is in direct line with Crab, the shear will drop free to the ground without jar. When tower has assumed vertical position, keep guy and hoisting ropes tight till plank is removed from bottom of tower and anchor posts are bolted to place. Then plumb and square tower, and fill anchor holes with cobble stone and earth, tamping same firmly every foot. Remove the ropes, adjust pump rod to proper length, connect same and see that all nuts are tight, oil mill, and let her go.

It is not known how common it was to use a crab winch to raise a windmill tower in Australia. Even in the USA it was not common practice, with many farmers using draft animals that were used for pulling agricultural equipment, to also pull the cables for raising windmill towers. Later, with the advent of the motor vehicle, cars, trucks and tractors would have been used. Recently in the Morawa district a 17ft Southern Cross R Pattern windmill on a 45ft tower was raised using a large tow-truck. The principle of using a gin pole and cables was still the same as it was over one hundred years ago, but instead of taking 5 to 6 hours with four men, it was done with two men in under 2 hours.